Companies from many industries are always looking for methods to stay ahead of the curve, streamline their operations, and enhance their products in the fast-paced and fiercely competitive business environment of today. Custom metal part use is one important factor that frequently goes unrecognised but is essential to promoting efficiency and creativity. From consumer goods and healthcare to aerospace and automotive, custom metal parts are now an essential part of the creation and production of a vast array of items and applications. This essay will examine the importance, advantages, and ways that custom metal parts are changing industries all around the world.

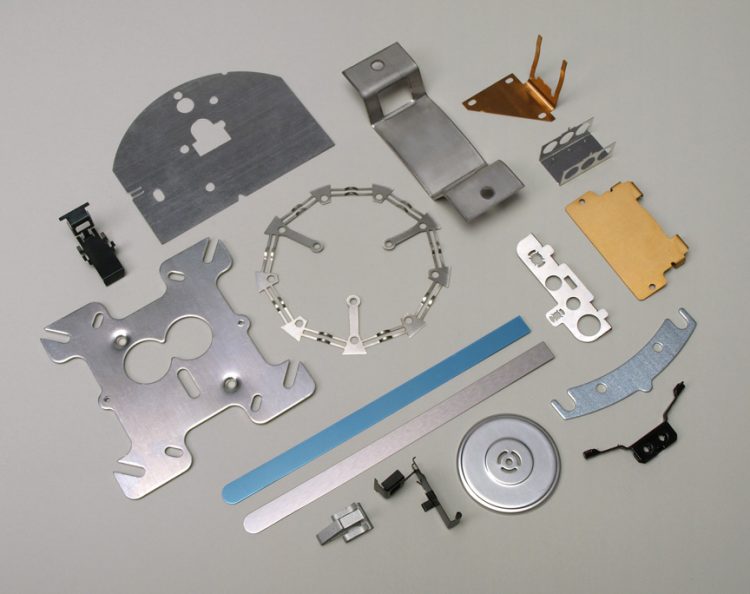

Fundamentally, bespoke metal parts are parts made and built especially to satisfy the particular needs of a certain product or use. Custom metal components are manufactured to the precise measurements, performance standards, and specifications specified by the customer, unlike off-the-shelf or standardised parts. Because of this degree of personalisation, businesses can produce goods that are more effective and efficient as well as more closely matched to their particular requirements and objectives.

Using custom metal parts has several benefits, one of which is the capacity to maximise product performance. When a component is created from scratch to serve a particular purpose, it can be developed to reduce weight, use of materials, and cost while maximising strength, durability, and efficiency. In sectors like aircraft and automotive, where every ounce counts and even the tiniest performance gain can have a big effect on fuel consumption, speed, and general effectiveness, this is especially crucial.

For instance, the aerospace sector uses bespoke metal parts widely to manufacture anything from fuselage and wing structures to engine brackets and landing gear. Custom metal components that are robust, lightweight, and able to survive the harsh conditions of flight can be produced by aerospace manufacturers employing cutting-edge materials like titanium and aluminium alloys together with exact manufacturing methods like CNC machining and 3D printing. Along with improving the aircraft’s dependability and safety, this also helps to save fuel and lower running expenses.

In the automobile sector, too, bespoke metal components are essential to the creation of electric cars, autonomous driving systems, and high-performance cars. Custom metal parts help car makers to push the envelope of innovation and produce faster, safer, and more efficient cars than ever before. These parts include everything from lightweight body panels and battery enclosures to engine components and suspension systems.

Custom metal parts also offer the important advantages of reducing lead times and streamlining production procedures. A component may be made more easily assembled, compatible with current systems, and produced with overall manufacturing efficiency when it is created especially for that use. By cutting production costs, reducing waste, and launching items into the market more quickly, businesses can gain a competitive advantage in their particular sectors.

Custom metal parts are, for example, utilised in the healthcare sector to make implantable components, surgical equipment, and medical devices. Working directly with engineers and medical experts, manufacturers can produce bespoke metal components that are exactly matched to the requirements of particular operations and patient anatomy. Patient comfort and recovery times are improved in addition to the precision and efficacy of medical therapies.

Custom metal parts can also help businesses make more aesthetically beautiful and user-friendly products. Custom metal components are frequently utilised, for instance, in the consumer goods sector to make upscale gadgets, furniture, and appliances. Manufacturers can make items that stand out in the market and attract to discriminating customers that appreciate both form and function by integrating distinctive designs, finishes, and features.

Custom metal part manufacturing usually requires tight cooperation between the manufacturer and the customer. The customer starts by giving a thorough list of the component’s specifications and needs, including its intended usage, performance standards, and any unique features or limitations. The manufacturer next collaborates with the client to improve the design, choose the best materials and production techniques, and produce prototypes for evaluation and verification.

Because the design may be improved and changed in response to user input and performance test findings, this iterative process offers a great deal of flexibility and customisation. Following approval of the final design, the manufacturer can use a range of cutting-edge manufacturing techniques, including CNC machining, casting, forging, and 3D printing, to produce the bespoke metal components.

Making sure that custom metal components are consistently reliable and of high quality throughout several batches and production runs is one of the main obstacles in the industry. This necessitates a stringent quality control procedure that includes testing, documentation, and routine inspections all during production. To guarantee that the bespoke metal components satisfy the necessary requirements and performance criteria, manufacturers also need to have a thorough knowledge of the characteristics and behaviour of various metals and alloys as well as the capabilities and constraints of different manufacturing processes.

Using bespoke metal components also means taking into account the requirement for continuous support and maintenance. Custom metal parts may call for specific knowledge and experience to maintain and troubleshoot, unlike ordinary parts that are readily replaced or fixed. Manufacturers need to collaborate closely with their clients to offer continuous technical assistance, replacement parts, and repair services so that the bespoke metal components function at their best all the way through.

The advantages of adopting custom metal parts much exceed the expenses and difficulties involved, even in spite of these difficulties. Custom metal parts are propelling advancement and expansion across a broad spectrum of industries by helping businesses to produce more creative, efficient, and effective goods. Custom metal part options are only going to grow as long as technology like 3D printing, sophisticated materials, and artificial intelligence keep developing, giving businesses fresh chances to distinguish themselves apart and keep ahead of the competition.

In summary, custom metal parts are essential to the creation and production of goods and uses in a wide range of sectors. Custom metal components have many advantages that are changing how businesses develop, manufacture, and market their goods. These include everything from reducing procedures and improving user experiences to enabling innovation. Custom metal parts are going to become more and more important as the need for specialisation and customisation rises, which will make them essential to the profitability and competitiveness of companies all over the world. Companies can reach new heights of productivity, creativity, and expansion and set themselves up for success in a constantly shifting business environment by realising the possibilities of custom metal parts and making the required investments in the required knowledge and technology.